Debugging a Bluetooth Module is akin to conducting a symphony; it requires precision, patience, and a deep understanding of the technology’s nuances. As wireless communication becomes increasingly integral to our daily lives, the need for reliable and efficient Bluetooth Modules grows. This article will guide you through the intricacies of debugging Bluetooth Modules, offering insights into the common issues encountered and the strategies employed to resolve them.

Identifying Common Issues

Debugging begins with identifying the problem. Bluetooth Modules can face a myriad of issues, from connection dropouts to interference and power consumption anomalies. The first step is to replicate the issue in a controlled environment, which allows for systematic troubleshooting. Common issues include:

- Connection Instability: Intermittent connections can be caused by weak signals, interference, or firmware bugs.

- High Power Consumption: Excessive battery drain may indicate inefficient power management within the module.

- Data Corruption: Inaccurate data transmission could be due to signal interference or faulty encoding/decoding processes.

Tools of the Trade

Armed with the right tools, debugging becomes more manageable. Essential tools for debugging Bluetooth Modules include:

- Serial Console: For firmware-level debugging, a serial console provides a direct line to the module’s inner workings.

- Protocol Analyzers: These tools help in capturing and analyzing the Bluetooth communication, identifying issues in the data packets.

- Bluetooth Scanners: Devices that can detect and display information about nearby Bluetooth Modules, useful for diagnosing connection issues.

- Power Meters: To measure the actual power consumption of the module, which can help in optimizing power usage.

Firmware Analysis

Firmware is the heart of a Bluetooth Module, and issues within it can manifest in various ways. Debugging firmware involves:

- Code Review: Thoroughly examining the code for logical errors or inefficiencies.

- Unit Testing: Isolating parts of the firmware and testing them independently to identify faults.

- Integration Testing: Ensuring that the firmware works harmoniously with the hardware and other system components.

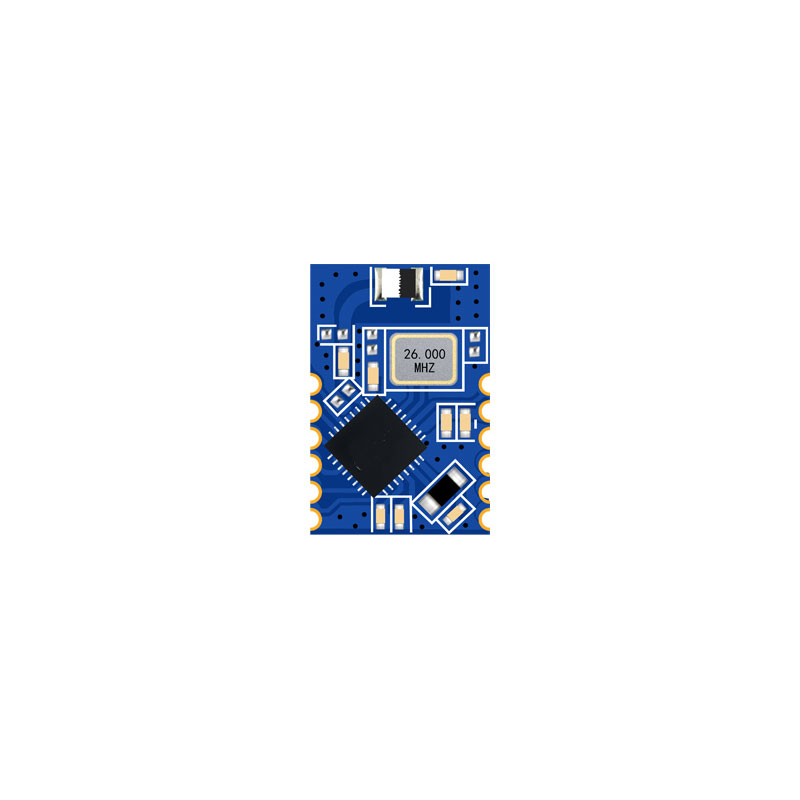

Hardware Inspection

Sometimes, the issue may not be with the software but with the hardware itself. A hardware inspection involves:

- Visual Inspection: Looking for any physical damage or manufacturing defects.

- Continuity Testing: Checking for breaks in the circuit using a multimeter.

- Solder Joint Inspection: Ensuring that all connections are secure and there are no cold solder joints.

Signal Integrity

Bluetooth relies on radio waves, and the integrity of these signals is crucial for the module’s performance. Debugging signal integrity involves:

- Antenna Placement: Ensuring the antenna is correctly positioned for optimal signal reception.

- Signal Strength Measurement: Using tools to measure the strength of the transmitted and received signals.

- Interference Detection: Identifying and mitigating sources of interference that could degrade signal quality.

Power Management Debugging

Power-related issues can be particularly tricky to debug. Strategies for power management debugging include:

- Current Consumption Measurement: Monitoring the module’s current draw under different conditions.

- Sleep Mode Optimization: Ensuring that the module is effectively entering and exiting sleep modes to conserve power.

- Power Supply Stability: Verifying that the power supply is stable and providing the required voltage and current.

Conclusion

Debugging a Bluetooth Module is a multifaceted process that requires a deep understanding of both hardware and software. By systematically identifying issues, employing the right tools, and employing a methodical approach to troubleshooting, developers can resolve even the most complex of problems. As Bluetooth technology continues to evolve, so too will the debugging techniques, ensuring that Bluetooth Modules remain reliable and efficient components in our increasingly connected world.